Why is Inventory Even Needed?

While frequently misunderstood, inventory levels are a direct result of supply chain process design. Supply chain processes that don’t synchronize with customer demand require inventory to buffer their lack of alignment. This shortfall is often addressed with demand forecasting, which has a long history of letting all parties down. Given this condition, there are really only four legitimate reasons for inventory:

1. Delivery is required in less time than it takes to produce the product

2. Product demand exceeds production capacity within the customer’s delivery window

3. The production cycle is out of sync with the demand cycle

4. Production is unreliable

All of these drivers are outcomes of insufficient process designs that lead to excess inventory costs for the organization. The Triple Play Chart provides insight into the extent to which process design drives up inventory costs and also identifies the potential for reducing inventory investment.

THE TRIPLE PLAY CHART

INVENTORY ASSESSMENT TOOL

What is a Triple Play Chart?

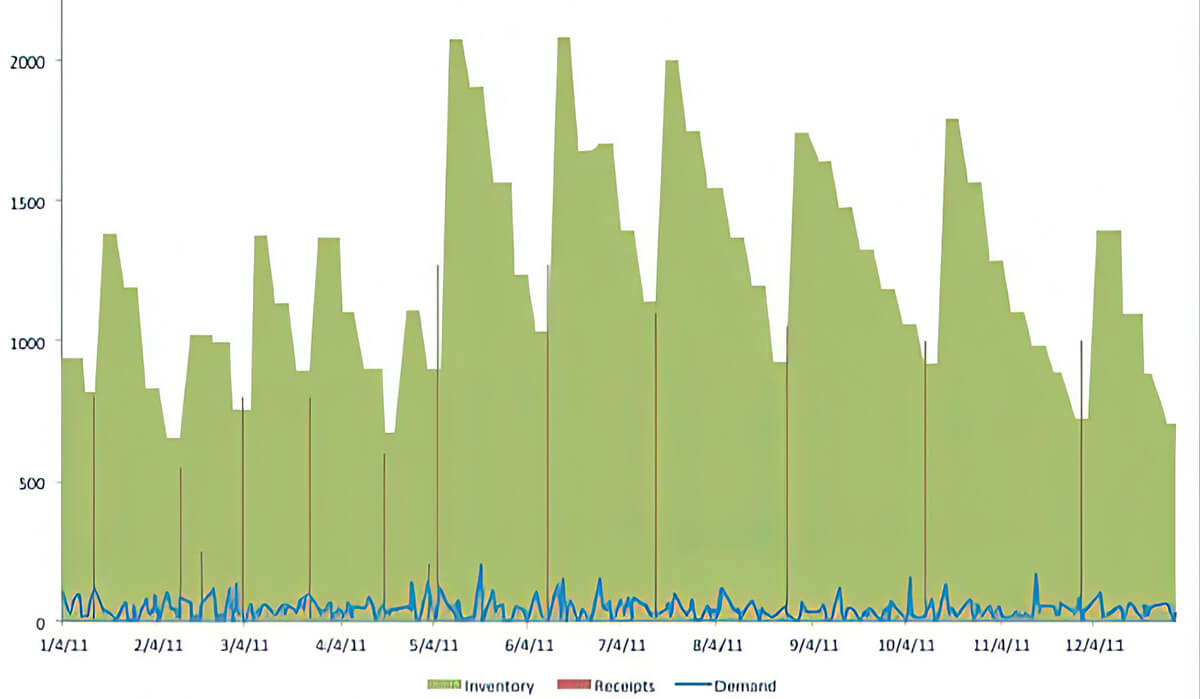

The Triple Play Chart (typically developed in Microsoft Excel) is a chart designed to assess the synchronization of supply and demand for a product produced by a given process. It delivers this assessment by simultaneously charting demand, supply, and inventory profiles within standard time buckets over an extended period of time, usually 12 to 24 months. The Triple Play Chart (example shown above) includes the following elements.

1. The Standard Time Bucket

Triple Play Chart construction begins by defining the time bucket that sets the demand rhythm. How frequently do customers’ buy or use the product produced by the process? Do customers buy the product daily, weekly or monthly, or even annually? This time bucket question is essential, as the answer sets the standard demand cycle for the process. We recommend that the time period studied be at least 12 months to accommodate seasonality. In the example shown above, the time bucket used is daily.

2. The Demand Profile

The Demand Profile (blue line in front) defines the volume of product ordered within each time bucket for the period studied. Using the daily time bucket, the question to ask is how many units of the product were ordered for each day for the last 12 months. The unit of measure should be defined as the smallest unit ordered by customers (typically each; less than a case). In the example shown, customers order this item on 239 days, with an average order size of 47 units.

3. The Supply Profile

The Supply Profile (solid red bars in the middle) defines the product volume supplied within the standard same time bucket for the period of time studied. The unit of measure must be the same as used in the demand profile. In the example, the process supplies this item on 13 days with an average delivery size of 823 units.

4. The Inventory Profile

The Inventory Profile (solid green area in back) defines the volume of units in inventory in between the supply process and customers at the end of each time standard time bucket. In the example, the average inventory quantity stored each day between the process and its customers is 1239 units.

Why is the Triple Play Chart a Great Inventory Assessment Tool?

The Triple Play Chart can be used for a variety of diagnostic purposes. Here are a few of the most useful.

1. The level of cycle matchup between supply and demand.

The first insight provided by the Triple Play Chart is the extent to which the supply cycle matches up to the demand cycle. In the example, the demand cycle is 239 days, while the supply cycle is 13 days. This shields a matchup ratio of 17.4: 1 (239/13), which is substantially out of sync. The ideal ratio is 1:1.

2. The supply capacity necessary to meet demand

The example shown illustrates that the maximum capacity required per day during this 12 month period is about 200 units. Since the average production Batch is 823 units, the production process has plenty of capacity to produce this quantity.

3. Demand variation

The example shown illustrates that about 75% of the daily demand is less than 75 units, which indicates a relatively predictable pattern for that item.

4. Supply variation

The example illustrates that supply varies greatly during this study, ranging from as low as 200 units to as high as 1275 units.

5. The level of excess inventory based on the supply-demand matchup

One of the more valuable features of the triple play chart is how clearly it illustrates the excess inventory carried by the process that is not supportable by any physical constraint. In the example shown, there are roughly 500 excess units of inventory being carried at all times greater than is necessary to support the cycle imbalance. This can be seen in the solid green background of inventory units in excess of the red line representing sales. While we would not recommend reducing inventory by 500 units without further inquiry, one can easily see how inventory could be substantially reduced without much risk.

6. The level of inventory reduction attainable by synchronizing supply to demand.

The example shown illustrates a substantial opportunity to reduce inventory in phases. The first phase would be to take down the excess inventory that is unsupportable by the business model. The second phase would be to further reduce inventory by increasing production cycles (for example, twice per month) and reducing production batch sizes.

What Doesn't the Triple Play Chart do?

The triple play chart does not explain causality for the performance. When reading a triple play chart, the analyst should consider a variety of underlying causes for why the process design delivers the results diagnosed by the triple plate chart. These include the following possibilities.

- The process has long lead-times

- The process lacks capacity

- The process has long change-over times

- The process lacks visibility into customer demand

- The process produces heavy yield loss

- The process is unreliable

- And many others

What we have found is that many of these causes are immediately addressable and can deliver substantial improvement fast. The value of the triple play chart is that it creates a new and transparent view that makes performance easy for the analyst to diagnose.

The Triple Play Chart is Extremely Valuable, but....

Let me offer one caveat in using the Triple Play Chart. It only diagnoses past performance. When conditions are substantially different going forward, this data must be evaluated in the context of what known changes are coming. The Triple Play Chart works excellent on a system that is stable. It is not as useful when future conditions differ drastically from the past.