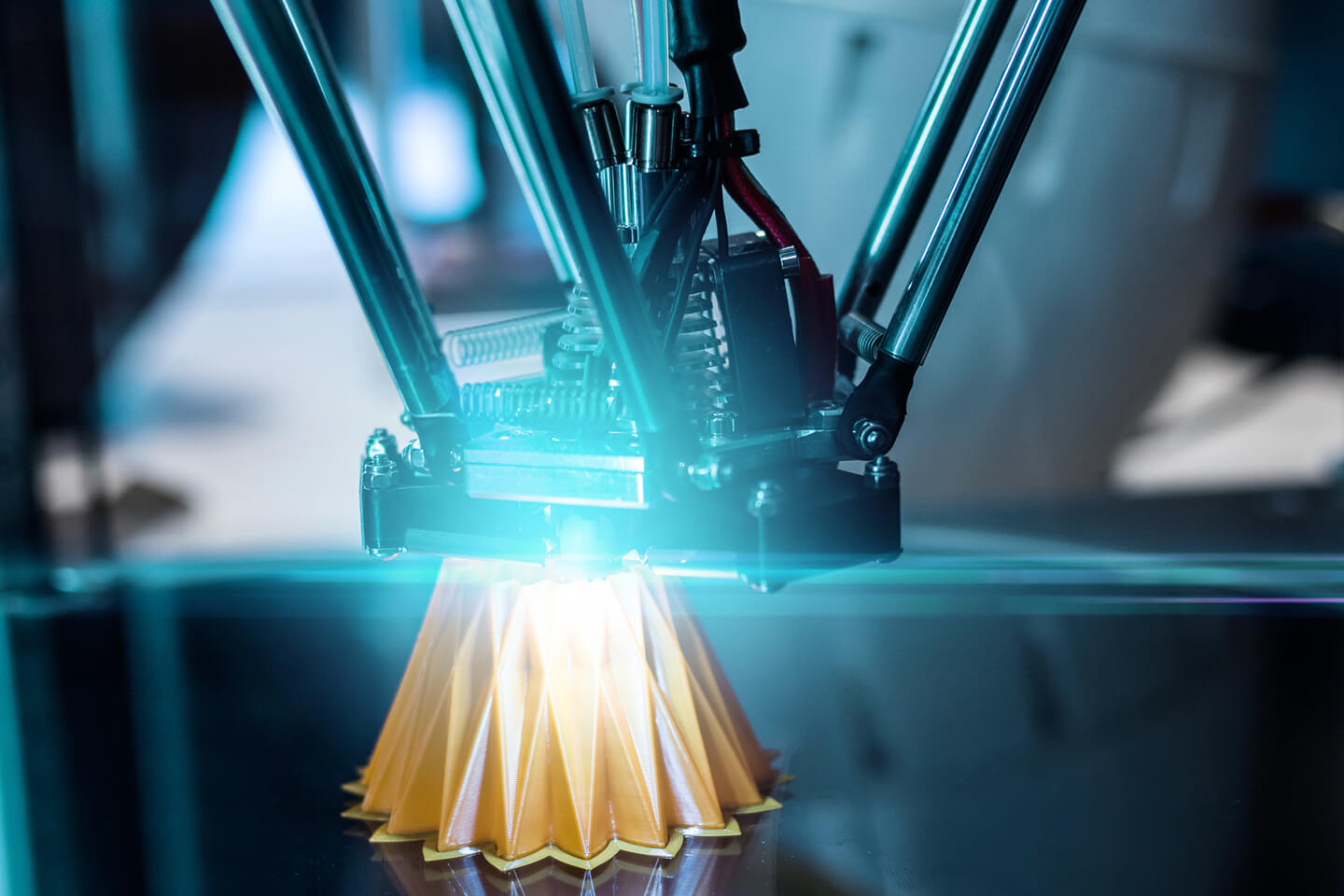

Since its inception, 3D printing technology has been growing and prospering. More and more people are associating with the idea of flexibly customizing parts and functional prototypes needed in their daily lives. The business class of new technology grows older, so emerging business opportunities are happening with 3D printing technology.

The growing popularity of 3D printing leads to the creation of newer business models. And to ask anyone, "Which 3D business model should you choose for your company?" Is like asking him or her to explain to all the business models that 3D printing companies follow in the current market. We'll do that for you!

Emerging 3D printing business models

We understand that trying to canvass any field's business models is to see that field in a limited way. For this reason, we would not state that "Below mentioned are all the 3D printing business models you can choose from!" Instead, we'd like to say that "Below mentioned are some of the most powerful 3D printing business models that have had higher success rates to date."

Manufacturing on-demand

This business model helps overcome the risk of balancing demand and supply. All thanks to the no-tooling-required property of 3D printing technology that lead-times for small batch production are shortened like no other. So, instead of manufacturing large batches according to the business practices observed over the years, you can produce on-demand.

A lot of renowned 3D printing service providers offer on-demand manufacturing. The completed product is manufactured using the 3D design file of the customer. Based on that, the supplier can provide instant quotes, and once the order is confirmed, the supplier can produce a few dozen or hundreds of parts or functional prototypes using 3D print farms.

MaaS

Digitization has led to making communication faster than ever in history. And hinged on this benefit, this shared business model is profiting many companies. The idea is simple and effective. Integration of manufacturing companies all over geographies using digital technologies!

Once that is achieved, the workload on any one of the integrated manufacturers is sensed and shared, before becoming an overload. Customer satisfaction through on-time delivery is the epicenter of MaaS. Analyzing and programming the customer's request for a part or functional prototype and then assisting the job to the most suitable facility that'll be most efficiently able to fulfill the request; is the exact area in which the flexibility of 3D printing and openness of digitization comes into play.

Supply chain consolidation

To show the significance of this business model, we'd like to share with you the results of a Gartner study conducted in 2018: 38 percent of supply chain managers are using 3D printing technology to simplify the supply chain and manufacture end-use parts in-house. And 47 percent plan to use this in the next two years.

The reason behind such positive feedback from people associated with this business model is the recent development in 3D printing technology that allows you to manufacture complex parts and functional prototypes with ease. Manufacturing such objects via traditional techniques was previously impossible. A flexible assembly that requires fabricated parts as individual components as well as a single unit, even when the geometry is complex can be manufactured via additive manufacturing. And such a part consolidation helps reduce the number of parts and lessens the product portfolio complexity.

Customizing on a large scale

This business model deals with the flagship of 3D printing technology, customization and the main limitation of traditional manufacturing techniques, standardization. The reason why this business model is favored over others is that consumers are demanding more and more personalized products.

3D printing technology provides a viable solution for manufacturing products specific to an individual's need on a mass scale. This business model is not profitable using traditional manufacturing technologies because of the large investment typically required. Whereas using a 3D printer, you can customize the needs of any consumer in the part or functional prototype they are demanding.

Direct to Consumer

A lot of companies prefer this business model because of the transparency it can provide. You'll find a lot of platforms that display the work of 3D designers openly to customers enabling them to download the file. This sort of business model is also advantageous for 3D designers who target a specific customer.

In fact, if you manage to develop a platform where not just one but many designers can showcase their work, they can learn from each other and connect with each other. Additionally, 3D designers can also learn about customer preference by seeing which design is getting the most downloads and a lot more.

In Conclusion

The entire 3D printing business model might appear similarly advantageous and limited to you at first glance. While they all provide benefit in their own unique ways, they also each have their own restrictions. To determine which business model is best, you can identify the prerequisites of each of these business models, and estimate the amount of time, money, effort, and investment each requires. Based on that comparison, you can select the best approach for your business.

Do not assume that one of these business ideas is more profitable than the other! Each one of these models provides benefits in the proper situation. Your challenge is to determine the business model that suits you the most by analyzing it within the parameters you can afford. If you go for manufacturing on-demand, you need to be prepared to provide customers with instant quotes. If you choose manufacturing as a service, you'd need an integrated network. Supply chain consolidation would likely require a larger investment in 3D printer technologies. Customization at a large scale would demand even more equipment investment. And the direct customer business model demands a transparent platform. So, it's up to you to choose your own strategy. Good luck!