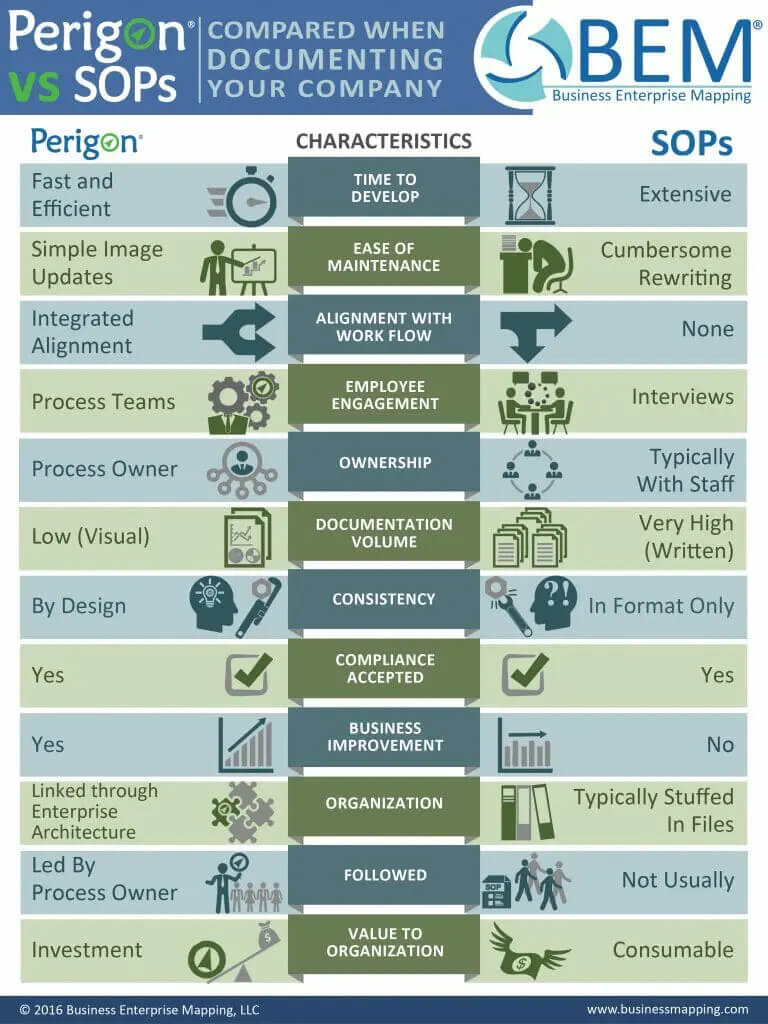

We are often asked by prospective clients to develop Standard Operating Procedures (SOPs) to document a firm’s work. Because we are a process-mapping firm, we frequently document workflows, but in a way that is different than the client initially expected. We know from extensive experience that SOPs are a poor, cumbersome way to document to work in any organization. I will briefly discuss some of their main shortcomings.

SOPs are very time-consuming to develop, open to interpretation, visually boring, and difficult to maintain. Because documentation specialists typically write SOPs, the people who use them do not own them; hence they are often forgotten and stored on a shelf until auditors come along for review. The value-added content in SOPs is hidden among the much more prevalent non-value-added material and, because most organizations need hundreds of SOPs, this can add up to substantial wasted effort. When using SOPs, workflow continuity is complex, difficult to follow, and inconsistent. We often find that companies with SOPs in place are still using Revision "A", even though the SOPs were written several years earlier, demonstrating that they are stagnant.

We prefer the much more robust process map. Summarized following are several reasons process maps provide better documentation.

Standard Operating Procedures (SOPs) Challenges

- Time to develop. SOPs take a substantial amount of time to develop, often 40 hours or more for a business process. For the same detail and understanding, process maps typically can be built in a few hours.

- Ease of maintenance. Because SOPs are typed instructions, they are difficult to maintain and require an extensive amount of time to rework. Process maps are visual diagrams that are easily modified using icons, symbols, and stencils.

- Alignment to workflow. SOPs are typically built from the bottom up. They are often confusing and present a difficult way to follow workflows. Process maps are built top-down, beginning with business systems, business processes, task, and knowledge. Workflow is designed directly into the documentation.

- Employee engagement. SOPs are usually written by staff members interviewing those who do the work, then writing narratives of what they have learned. Process maps are best built-in team workshops by asking those who do the work to participate in the diagramming of that work. The workshop method substantially increases employee engagement and understanding of how work gets performed.

- Ownership. SOPs are rarely understood and owned by those who do the work, because they are typically done by staff members who put them in file cabinets to be accessed when necessary. Process maps are incorporated into their workflow itself, which facilitates high employee ownership and easy identification.

- Documentation Volume. The volume of documentation required when using SOPs is extensive. This is because all work is modeled through written narratives and written instructions. Process maps are largely expressed through visual models and require much fewer words and documentation to understand.

- Consistency. Because many different individuals often write SOPs, there are no readily accepted standards for consistency. Process maps have consistent standards and an accepted format that leads to consistent workflow documentation.

- Compliance acceptance. SOP’s are the most readily accepted method for regulatory compliance today. Due to the shortcomings discussed here, however, process maps are increasingly replacing them as the preferred method for documenting how work gets done in an organization. SOPs will always have their place in work instructions, however the written word should be minimized for purposes of understanding and ease of maintenance.

- Business improvement. SOPs are generally not used as a business improvement tool but only to document how work gets executed. Process maps are primarily used for business process improvement as a better way to document how work is being performed and identify improvements for the future.

- Organization. SOPs are very difficult to organize and maintain because they have an extensive instruction narrative. Because process maps are developed according to a structured hierarchy, they are much easier to organize and maintain.

- Followed. Those who do the work are best positioned to define and improve the work. Because they require an extensive amount of time to develop, SOPs are rarely done by those who do the work. Process maps are more easily developed by those who do the work because they are faster, more visual and an easier way to capture workflow understanding.

- Value to the organization. SOPs are generally consumable documents that grow out of date quickly. Process maps are investments in an organization’s understanding of how the business model works, along with plans to continue to improve that work in the future.

Process maps can be very versatile, with many capabilities and uses. They are very visual and contain about ten main standard symbols. When done right, there is very little deviation in map construction, consisting of tasks, decisions, inputs, and outputs. They can be read and understood within five minutes and used quickly by everyone in a business, from the stockroom to the boardroom. In comparison, SOPs can be extremely long, take many days to develop, and include thousands of words, which leaves them wide open to interpretation. It can take many hours to read and understand SOPs, due to their unclear connectivity and lack of structure.

Further Reading: THE PERIGON METHOD